Page 2 of 3

Posted: Fri Sep 09, 2011 1:53 pm

by TwoStroke Institute

Blowdown won't affect the power spread, that's a host of other factors. The stock KR has the minimum needed.

Posted: Fri Sep 09, 2011 10:53 pm

by Mark66

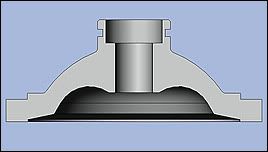

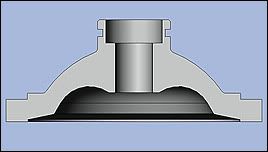

I think TwoStrokeInstitute means the area round the plug should look more like this.

Posted: Sun Sep 11, 2011 1:42 am

by JanBros

TwoStroke Institute wrote:Nice work Jan, I'll give you 9/10

you can downgrade that one.

apparently the holes on the left (off the picture) are not in the middle.

http://i54.tinypic.com/nbyemq.jpg

thought it was a fabrication error (less material on one side of the plu-hole) , but apparently it's mine

Posted: Thu Sep 15, 2011 11:10 pm

by JanBros

Posted: Fri Sep 16, 2011 12:41 am

by KR-1R

GOOD JOB - nice work

JanBros wrote:anybody know if it's a good idea to make some sort of grooves at the back to increase the surface for better cooling ? or will it disturb the waterflow too much ?

as answered - neither the race teams (app) or VHM do, so NO is the answer

the IDEAL I.C. engine would run at flame/combustion temperature

that way there would be no heat differential that would suck heat power from the expanding combustion process

of course not possible with common materials (and pre-ignition without direct injection)

in the real world most of the engine has to run at much lower temperatures (with losses to cooling and atmosphere)...

the benefit of efficient cooling is that incoming air stays cooler/denser for as long as possible

... to summarise if you run the chamber cold it sinks heat to the cooling system removing power obtained from combustion (less work done on piston)

Posted: Fri Sep 16, 2011 9:54 am

by 500bernie

Great work Jan

You will have to let us all know when you are going into production, so we can all get our not so good heads fitted with inserts

Posted: Sat Sep 17, 2011 8:39 pm

by JanBros

If I may say so myself : starting to look really good

added a stop to prevent the insert from spinning when tightning the spark plug. may not look "professionel", but does the trick.

500bernie wrote:Great work Jan

You will have to let us all know when you are going into production, so we can all get our not so good heads fitted with inserts

might consider it, but it's very time-consuming

, can't do it for free ...

Posted: Wed Sep 21, 2011 10:17 pm

by JanBros

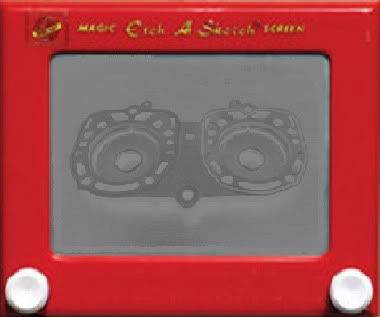

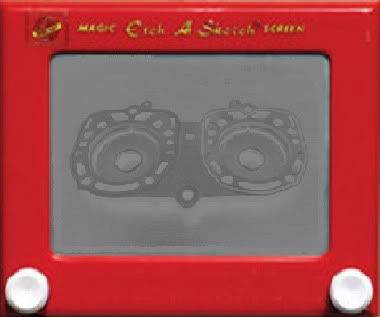

did a flip horrible job the last days : O-ringing the outside of the head. it's like that red drawing game from the 80's (?) where you have a knob for horizontal and one for vertical lines. Same way I had to do this on my mill

and because the used mill (2 mm) is so small I couldn't cut it in one time, had to go 3 times round for the needed dept per head

next : sealing the KIPS-valves.

Posted: Thu Sep 22, 2011 9:10 pm

by JanBros

last part :

O-rings arround the KIPS-valves. Now any imperfection won't result in waterleaks, 'cause everything is surrounded by seals

Posted: Fri Sep 23, 2011 9:45 am

by scooble

can VHM inserts be made to fit or is that unfeasible?

Posted: Fri Sep 23, 2011 8:06 pm

by 500bernie

JanBros wrote:did a flip horrible job the last days : O-ringing the outside of the head. it's like that red drawing game from the 80's (?) where you have a knob for horizontal and one for vertical lines.

Hi Jan,

Etch a Sketch

Nothing that is quality comes cheap, I am sure there are plenty of members that do not have the skill to do what you can do

, but would be prepared to pay for it

Cheers,

Bernie

Posted: Fri Sep 23, 2011 9:18 pm

by Howie

Hey Bernie, did you etch a sketch a Kr1s head just for that picture (

)

Just for the record I absolutely hate etch a sketch, its so bloody frustrating, all I wanted to do was draw a diagonal line, a straight diagonal line

Its not too much to ask

Posted: Sat Sep 24, 2011 11:01 am

by JanBros

scooble wrote:can VHM inserts be made to fit or is that unfeasible?

if you can give me some dimensions I can check, but shouldn't be a problem

Posted: Sat Sep 24, 2011 11:12 am

by scooble

sorry Jan, don't have any dimensions. I was thinking from the point of view that VHM inserts are off the shelf for a number of models, therefore, if possible, may only require half the machining. Outstanding work by the way, good to see the resourceful KR spirit alive and kicking which is sadly lacking on many other forums

Posted: Sat Sep 24, 2011 2:03 pm

by 500bernie

Hi Howie,

Sadly no, it is a modified copy of the photo of Jans work (note the groove for the O ring).

Cheers,

Bernie