Page 1 of 6

Engine project

Posted: Wed Feb 10, 2016 4:29 pm

by DougB

Re: Engine project

Posted: Sat Feb 13, 2016 1:06 pm

by DougB

Re: Engine project

Posted: Fri Feb 26, 2016 10:30 am

by DougB

Re: Engine project

Posted: Sun Feb 28, 2016 10:27 pm

by 500bernie

Hi Doug,

Cracking work =D> =D> =D>

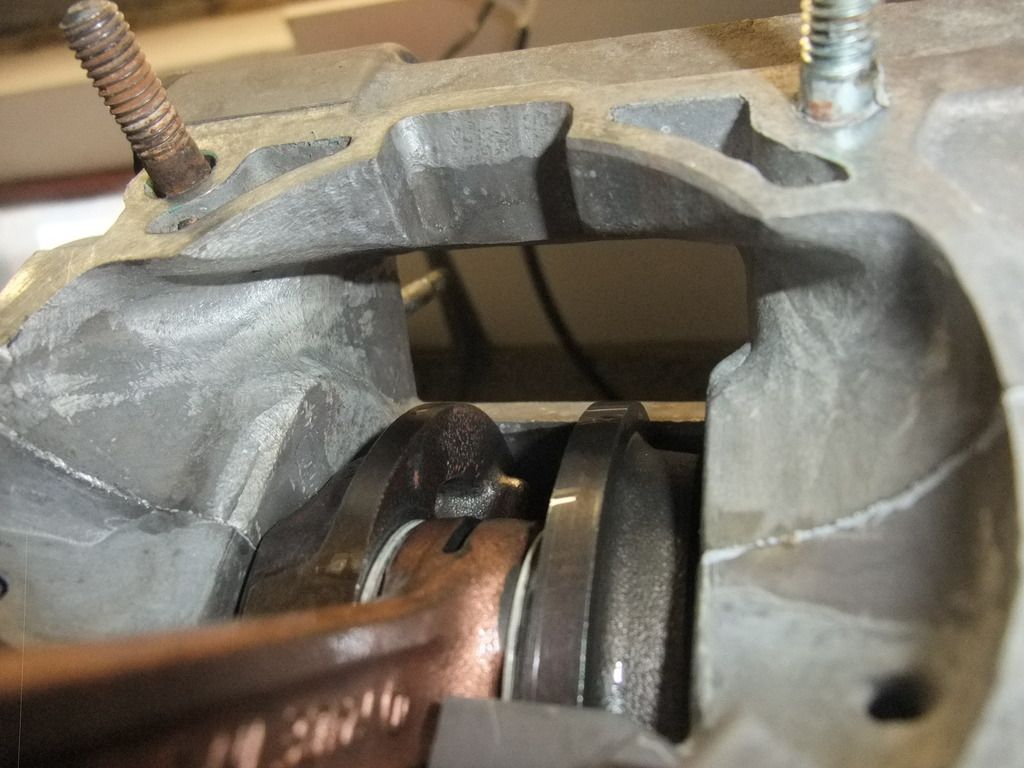

On the crank oil feed holes, where you have streamlined it all, I thought the flat recessed area where the hole is was a collection area for the drip feed to the crank main bearings. Does smoothing it all off reduce the amount of collected fuel/oil mix from getting to the mains?

Cheers,

Bernie

Re: Engine project

Posted: Sun Feb 28, 2016 11:08 pm

by DougB

Tricky one this Bernie! Although the holes allow oil to drip down at standstill, when the engine is running I don't believe there would be liquid oil hanging around there. Looking at the flow, I think these holes allow mixture to flow from the deadspot behind the main bearings (between the bearing and the crank seal) and the transfer chamber. I think on the downstroke the piston creates pressure in the lower case/crank, as the transfers open that pressure releases and those holes allow some of the mixture charge to flow through the main bearings and up the holes, lubricating the mains as it does, so the main flow through those holes is mainly upward, although as speed changes it may well be slightly bi-directional (the venturi affect of gas passing up the transfer would also draw air up the hole I think).

Either way I do think I might have created a problem by increasing the length of the holes so also increasing resistance so reducing the flow through them. I think I first saw the mod in Ben's guide to gas flowing the cases but the pics from that thread have since gone so it's from memory.

I might be totally wrong, and if I've misjudged this there'll be 1 outcome, I'll be rebuilding the crank pretty soon! Part of this though is I like making these sort of decisions and seeing the outcome.

One thing in my favour is the quality of modern 2 stroke oil and the fact that roller mains need very little of it to survive.

We'll find out soon, the whole thing is trial and hopefully not too much error.

Re: Engine project

Posted: Mon Feb 29, 2016 3:17 pm

by Big.mac

Nice work. I've never been brave enough to do any porting work myself for fear of getting it wrong.

Re: Engine project

Posted: Mon Feb 29, 2016 5:26 pm

by DougB

At least as it's a spare motor that needed a rebuild I don't mind messing so much but I'll be gutted if I really screw anything up. Once it's on the road I'll be heading for a setup day on the dyno so I'll be putting the figures up, good or bad!

Re: Engine project

Posted: Mon Feb 29, 2016 7:30 pm

by JanBros

I did it to, filling up arround that hole, but aparently in the aprilia gp engines it's not filled so I won't do ir again and probably the next time I open my engine, take it out again.

Re: Engine project

Posted: Thu Mar 03, 2016 4:10 am

by James P

bozbridge wrote:...and the fact that roller mains need very little of it to survive.

Did I miss the fact that you are using roller main bearings instead of the standard ball bearings Doug?? If so, I'm intrigued to know the details and how/why you made the decision to go that way.

Thanks & regards,

James

Re: Engine project

Posted: Thu Mar 03, 2016 6:34 am

by Luders

Yes like Jan I don't do that mod anymore.

I can't say I have ever noticed any issues which could be attributed to this, but if the GP spec is not like it, why would we.

Did you not get my email bozbridge?

Re: Engine project

Posted: Thu Mar 03, 2016 6:36 am

by Luders

Just to add, you have done a good job of the top halves which is what matters, well done.

Re: Engine project

Posted: Thu Mar 03, 2016 9:32 am

by DougB

Thanks for the comments..

Sorry Ben I didn't get an email, not sure but the filter can be a bit keen so sorry it might have sent it the wrong way and I never saw it.

The cases, well I've done the filling now and it was good practice. Jan & Ben I'm guessing if the filling around the front oilways doesn't do any good at least it shouldn't do any harm? As Bernie pointed out it could affect the lubrication but as for power I'm assuming now it's just not going to improve much but as long as it's not hurting I'll leave it (it certainly makes the line in the casings look much cleaner

)

James it's my wording, the mains are on ball bearings not roller, that would be far more engineering than I'm planning to put into it!

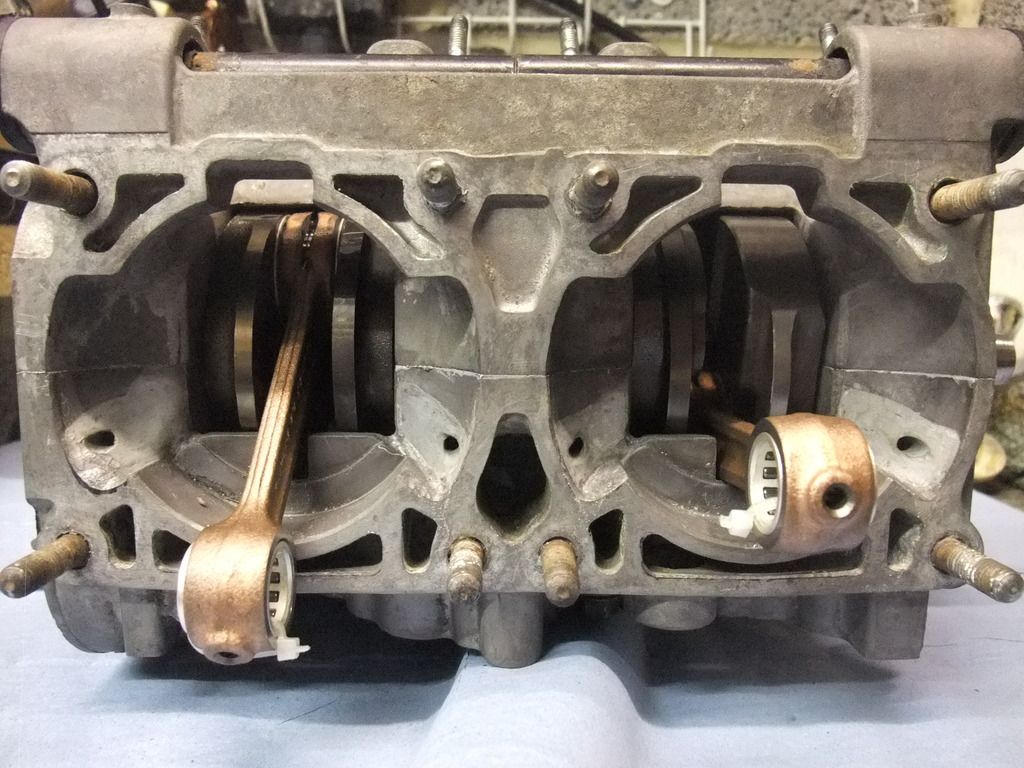

Bottom end back together, waiting for the barrels to come back so I can get on with setting all the top end up.

Re: Engine project

Posted: Tue Mar 22, 2016 10:52 pm

by DougB

It's been a few weeks but the barrels are back, got my delivery from BDK so now I've got a full set of valves so just finished off a bit of matching the Kips ports and a little bit of tidying up on the barrels. Now can start checking the top end and squish and it'll finally be ready for finishing off I think..

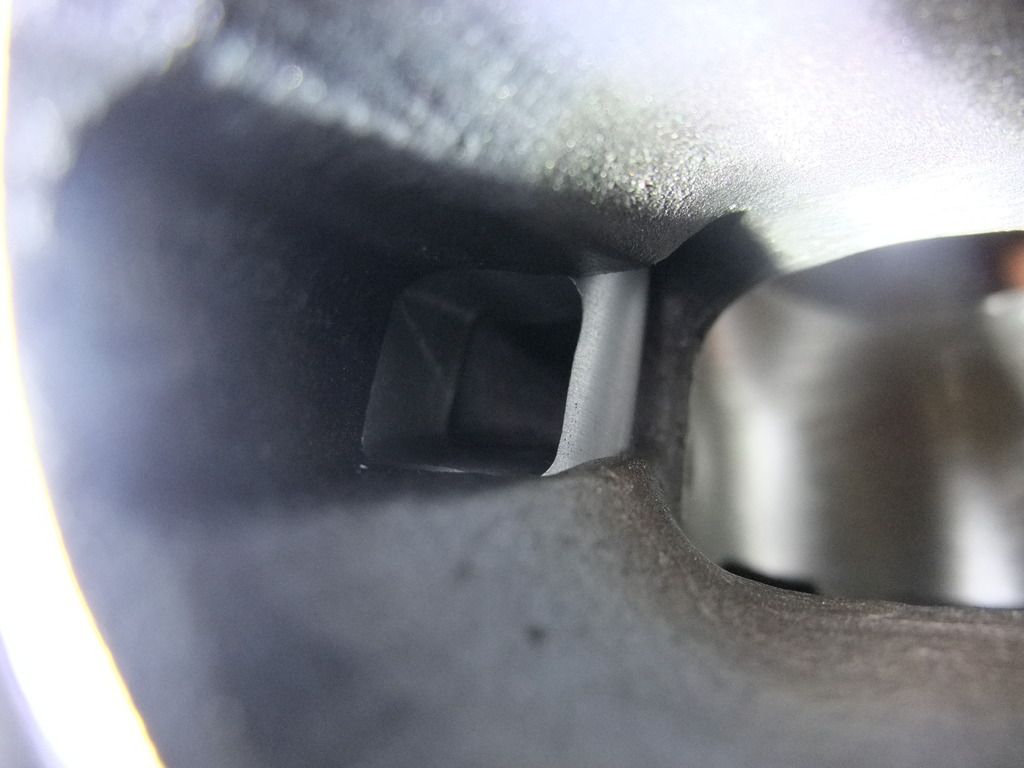

New kips valve in the barrel, shows the mis-match on the top and bottom

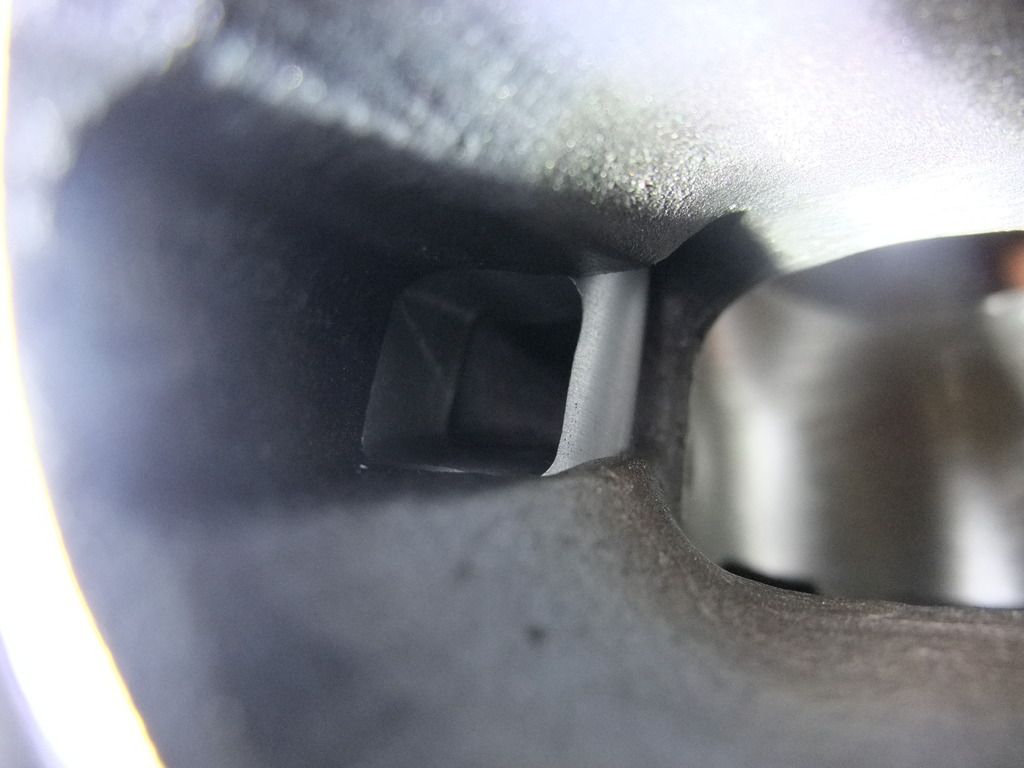

After a bit of Dremel time

Glad I spent a day sorting out the bench parts washer, coming in handy

Re: Engine project

Posted: Wed Mar 23, 2016 7:33 am

by Luders

Nice work, you should book on to the Donington track day in June with it.

Re: Engine project

Posted: Wed Mar 23, 2016 9:21 am

by DougB

I would've booked on at Donny already but I'm at the TT, only getting back on the Wednesday and sadly back at work on the 16th. I'll be at the Cadwell PSB weekend again to give it it's first bit of track time.