Page 2 of 5

Re: C3 restore project - Info needed from those who have don

Posted: Sat Jan 10, 2015 9:14 am

by James P

kiwisteve74 wrote:...I can't find a complete Oem gasket set listed either? I guess you have to buy individualy, the Athena kit makes me nervous. Are there any other options?

If you want a complete gasket set, try this:

http://www.ebay.com.au/itm/89-92-KAWASA ... 2a42a34e08

These are well priced and I have found Cruizin Image Co a good seller to deal with. The only problems with the set is that the head gasket is questionable (some people have experienced leaks) and that there is no water pump cover gasket. You can still buy the head gasket from Kawasaki and I believe Dan McBride (maccas) has already had the water pump cover gaskets remade (as well as some others, as Ben mentioned). I have also had water pump cover gaskets remade (

viewtopic.php?f=1&t=11272&hilit=water+p ... +australia).

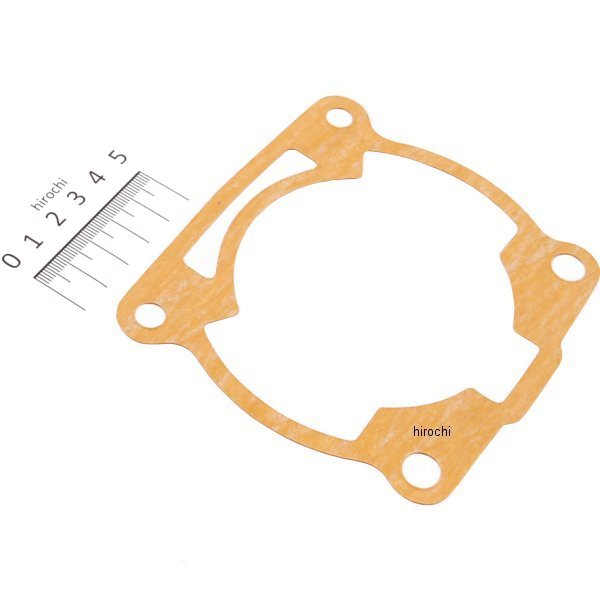

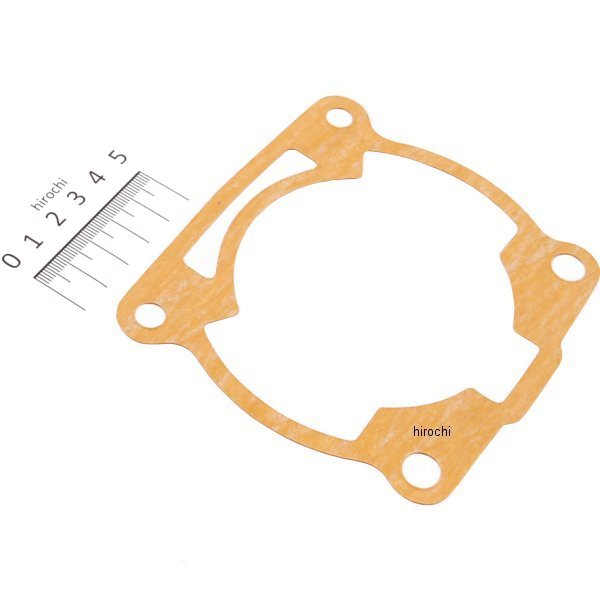

An advantage of Dan's gaskets is that he offers several thickness options for the base gaskets - handy for setting squish clearance without machining! Dan may offer a complete gasket set (without head gasket though).

Some of the other gaskets are still available from Kawasaki too.

Regards,

James

Re: C3 restore project - Info needed from those who have don

Posted: Sun Jan 11, 2015 11:04 am

by kiwisteve74

Great info guys, thanks. I will PM Dan for some prices.

I agree totally with an oem head gasket, have already talked to a mate who owns a kawasaki dealership for a price.

Re: C3 restore project - Info needed from those who have don

Posted: Sun Jan 11, 2015 7:58 pm

by KR-1R

OEM base gaskets are ¥420 each = NZ$4.7 = £2.3

OEM head gaskets ¥3130 = NZ$35 = £17.5 (>£22 in UK)

theres already a few sets NZ side if you need them :-"

last time I checked NZ prices head gaskets were NZ$60, bases $10

other small items such as Genuine caliper seals etc are approx half GBP retail ex Japan

I doubt the NZ Kwak dealer will get anywhere near Japan retail price with our currently high dollar$ to ¥en

Re: C3 restore project - Info needed from those who have don

Posted: Mon Jan 12, 2015 9:20 am

by kiwisteve74

So they may be some in NZ Dan? , ive sent you an email mate.

Re: C3 restore project - Info needed from those who have don

Posted: Mon Jan 19, 2015 9:17 am

by kiwisteve74

Ok, so I now have gaskets. Now I need Pistons, I see matika are available in different sizes, how do i work out which I need? I get that you measure the cylinder a 3 places with a micrometer but how much clearance should there be? I've never found too much wear on an RGV cylinder so normally just go for standard. Are the KR1s cylinders nikasil? They look cast compared to the shiney RGV cylinders?

Re: C3 restore project - Info needed from those who have don

Posted: Mon Jan 19, 2015 11:34 pm

by mellorp

On your std pistons check the clearance. If it's in tolerance maybe just get new rings. If it's out of tolerance get new piston kits (

mitaka or what ever) and send them and your barrels to be replated and dressed.

Re: C3 restore project - Info needed from those who have don

Posted: Tue Jan 20, 2015 8:32 am

by Luders

Pistons typically come as type A B or C, alternatively 96, 97 or 98.

Your piston clearance should be around 0.04mm and as it wears beyond the tolerance (around 0.07mm), you buy the next piston size up and send the barrel with new piston for honing. This process is repeated to size C or 98 pistons. Once you exceed tolerance on your largest pistons, you need to send them away for replate and hone back to your A or 96 size pistons.

Your cylinder walls sound original by how you'rve described them.

Your standard cylinder bore tolerance is 56.03mm on the upper limit.

Re: C3 restore project - Info needed from those who have don

Posted: Tue Jan 20, 2015 10:06 am

by kiwisteve74

Cheers guys, so are they a plated bore? Chrome? Nikasil? I'm just used to seeing that shineey mirror like finish on an rgv cylinder when you pull them apart.

Re: C3 restore project - Info needed from those who have don

Posted: Tue Jan 20, 2015 11:31 am

by Luders

They were nickel plated originally, which had a dull finish to it

Kawasaki Electrofusion process

Posted: Tue Jan 20, 2015 10:52 pm

by KR-1R

Kawasaki trade marked '

Electrofusion' process - was said to be nikasil (nickel silicon) at the time (

sic magazines) but may have been a molybdenum+steel (hard chrome?) coating fused to the cast aluminium cylinder bore

Kawasaki changed the process and/or composition in 2003 (and perhaps also at some other time in between)

I recollect them (OEM new) to be hard and shiney and mildly rustable (less likely to be nickel composition?) - replated ones usually dull with cross hatched hone for better lubricity

>2003 = KHI MX cylinders with composite of nickel-phosphorous alloy, inorganic materials like ceramic, silicone carbide and some organic materials

different replating outfits can offer different plating materials: such as Cermets - combing ceramic (hard particles) in a metal matrix (soft)

Aptec and replating:

http://kr-1s.co.uk/forum/viewtopic.php? ... 003#p49944

Motorcross and Off-Road Motorcycle Performance Handbook - Eric Gorr

"There are three types of plated cylinders, Kawasaki Electrofusion, hard-chrome, and nickel silicon carbide. There are several variations of the nickel silicon carbide process but the most common trade name is Nikasil. The nickel-based processes have many advantages over hard-chrome, Electrofusion, and sleeving. Nickel attracts oil and is an excellent carrier material for silicon carbide particles, a wear resistant material that carries the load of the piston. This material is electro-plated right on to the aluminum cylinder for the optimum thermal efficiency. Nickel can be honed with diamond stones which leave distinctive peaks and valley scratches in the cylinder wall which retain oil and provide a certain bearing ratio between the running surfaces of the bore. It's possible to rebuild a plated cylinder by fitting it with a sleeve. However you can expect to pay more for bore maintenance over the life of the bike, and lose thermal efficiency and horsepower. Plated cylinders are harder and last longer than sleeved cylinders. Kawasaki cylinders with the original Electrofusion coating or hard-chromed cylinders can be repaired with nickel plating or sleeving"

1979 air cooled KX250...Cycle World January 1979 <<< click

Six explosions of l.l5mm molybdenum wire using 16.000 volts and nine explosions of 1.6mm carbon-steel wire using 13,000 volts produce a porous Electrofusion surface approximately 0.070mm thick. The thin coating transfers heat very quickly enabling closer cylinder to piston clearances

Piston Sizes clearances

Posted: Wed Jan 21, 2015 3:25 am

by KR-1R

piston size tolerances (depends on manufacturer) for 56mm bore

why your barrells are stamped A, B , or C on top of exhaust duct

the first cylinders cast usually A spec - tighter bore - supposedly as tooling to produce wears out the clearance gets looser hence bigger pistons to compensate

A 55.95mm

B 55.96mm <<< STD default supply

C 55.97mm

D 55.98mm (were not for available KR)

when the new Mitaka KR-1 copies came out they were advertised in different toletances above - shop around and see if that is still the case

available 55.94, 55.95, 55.96, 55.97

http://kr-1s.co.uk/forum/viewtopic.php? ... aka#p82603

check also the shipping PJME was excessive

Re: C3 restore project - Info needed from those who have don

Posted: Wed Jan 21, 2015 11:29 am

by Top-shaggy

That's really interesting Danny..

The AR125 barrels are also stamped A, B, C under the exhaust port

I was told by Kawasaki it was the location of manufacture.. They didn't say anything about a difference in tolerance ..

Makes sense though

Re: Kawasaki Electrofusion process

Posted: Thu Jan 22, 2015 10:28 am

by James P

KR-1R wrote:...Kawasaki changed the process and/or composition in 2003 (and perhaps also at some other time in between)...

I did read somewhere that Kawasaki changed from Electrofusion to Nikasil in 2003 - can anyone confirm?

Regards,

James

Electrofusion Nikasil Ceramic nickel-phosphorous cylinder plating

Posted: Thu Jan 22, 2015 6:52 pm

by KR-1R

Re: C3 restore project - Info needed from those who have don

Posted: Fri Jan 23, 2015 9:31 am

by James P

Very interesting - thanks for that Danny. Is that KX manual page from 2003 by any chance (the internet told me that the "M" model was introduced for 2003)?

The description of the material is a bit vague, although using terms like "nickel-phosphorous alloy" and "silicon carbide" makes it sound a lot like Nikasil

. No doubt Kawasaki has its own special mix though, especially so it can claim that the coating is being used for the first time in a two-stroke engine!

Regards,

James