Page 2 of 2

Re: my kr1s c3 started from here

Posted: Wed Jan 16, 2019 8:08 pm

by 500bernie

Hi Gerrit,

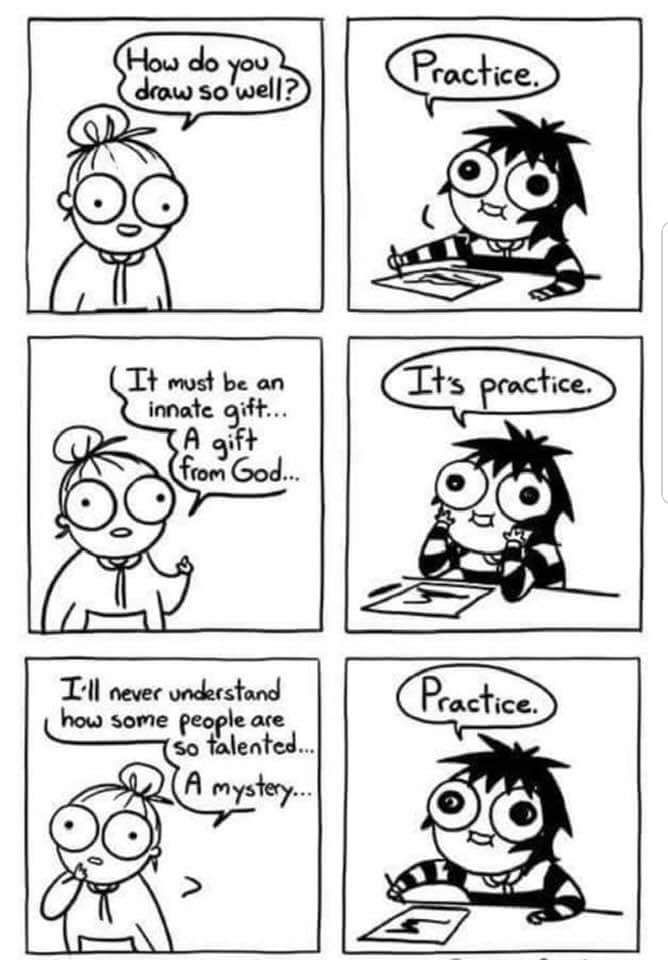

Patience and practice

Re: my kr1s c3 started from here

Posted: Wed Jan 16, 2019 8:41 pm

by SP_BOTT

Yes nice repair there, what size sheet have you used? did you double it up to give the thickness required, as the fairings look like they have a raised and thicker outside edge. Have re-done a few horrific repairs myself, and got this very same one to do when the weather gets a bit warmer.

Re: my kr1s c3 started from here

Posted: Wed Jan 16, 2019 8:51 pm

by 500bernie

I use 3mm thickness.

The main reason is that the overall thickness is 6mm, but the overlap/fixing points are 3mm thick.

Happy to make up an inspection corner replacement section for you if you want?, just let me know which side you need. (Or send me your fairing).

Cheers

Bernie

Re: my kr1s c3 started from here

Posted: Thu Jan 17, 2019 12:39 pm

by Shotgunsimp

Having done a bit of bodywork and lots of restores in my time this thread has made me realise I need to step my game up on this KR1s!!

WOW.

just WOW

Well done both.. Really impressive.

Simp

Re: my kr1s c3 started from here

Posted: Thu Jan 17, 2019 1:30 pm

by 500bernie

Hi Simp,

Thanks for the comments.

There are no industry secrets on this forum, we are all here to help other owners do the best they can for their bikes. I can polish metal and melt plastic, some of the other members are blessed with exceptional design and engineering skills

Looking forward to seeing what you are doing with yours.

Cheers

Bernie

Re: my kr1s c3 started from here

Posted: Thu Jan 17, 2019 6:51 pm

by KR-1R

eg for the thickness reinforcing pad at mount - what/how did you bond it - products ?

eg for cutting - use a slicing disk or jigsaw or hacksaw -tools ?

Re: my kr1s c3 started from here

Posted: Thu Jan 17, 2019 9:28 pm

by 500bernie

Hi Danny,

All very low tech I am afraid.

Sheet is covered in masking tape and marked up.

Basic shape is cut by scoring a straight line along one edge of the shape with a Stanley blade, then flexed to snap off the waste. Cutting discs generate too much heat and distort the sheet. Hacksaws, jigsaws are messy and need too much reworking to obtain a straight edge.

This is repeated until the basic outline remains, finishing is completed with sandpaper (by hand). I found 120 grit the most effective for removing material and giving a nice finish to the edge of the material.

Bonding is done initially with a thin coat of solvent adhesive, multiple points are melted through and the edges are bonded using a soldering iron then finished with sandpaper.

I will dig out some "work in progress " photos and post them.

Cheers

Bernie

Re: my kr1s c3 started from here

Posted: Mon Feb 25, 2019 11:57 pm

by c&c

Of course it is a gift from God..

Sing along..

" bind us together lord

bind us together lord

these fairings that are broken..

Re: my kr1s c3 started from here

Posted: Wed May 01, 2019 10:09 pm

by Rolex