Page 6 of 7

Re: Hybrid project

Posted: Sat Sep 19, 2020 5:40 pm

by Gerrit

I just weighed one of the RGV legs and it weighs 4.0 kg, with oil (quantity unknown). So assuming your legs were weighed with oil, Jan, the difference with the ZX6 leg is 0.4 kg- and it's 0.8 kg lighter than the ZXR400H leg. It would be interesting to compare the wall thicknesses and lengths of the stanchion tubes and weights of various other parts to see where the difference of 0.4 kg comes from.

Re: Hybrid project

Posted: Sat Sep 19, 2020 11:32 pm

by JanBros

zx6 was also weighted "ready to use".

like I already said : most of it comes from the steel inner legs.

I've got 2 set's of these forks, one I bought with a bended led. I've straightened inner leg's many times and it was obvious that less force was needed. so the gain is "double", as it's sprung weight.

Re: Hybrid project

Posted: Sun Sep 20, 2020 12:07 pm

by KR-1R

.

.

R6 fork leg is 3.967 kg, 735mm

Re: Hybrid project

Posted: Sun Sep 20, 2020 4:16 pm

by Gerrit

From which model RGV is that leg, KR? vj23? It doesn't look much like my legs which are definitely vj22.

I stripped one leg and measured the ID of the stanchion tube, which is 37 mm. The OD is 41 mm which leaves a wall thickness of 2 mm. I don't think that can be safely reduced any further, so the weight advantage of the ZX6 forks is presumably caused by lighter internals.

Re: Hybrid project

Posted: Sun Sep 20, 2020 5:18 pm

by JanBros

Gerrit wrote: ↑Sun Sep 20, 2020 4:16 pm

From which model RGV is that leg, KR? vj23? It doesn't look much like my legs which are definitely vj22.

he says it's from an R6

Re: Hybrid project

Posted: Sun Sep 20, 2020 6:23 pm

by Gerrit

OOPS, I misread RG!!!!!!!!!

Re: Hybrid project

Posted: Thu Nov 05, 2020 5:31 pm

by Gerrit

Minor update: I had five shallow grooves cut into the top of the upper tubes at 5 mm spacing to aid in adjusting ride height at the front end:

They will now be sent off for re-anodising.

Re: Hybrid project

Posted: Sat Nov 21, 2020 11:23 pm

by Gerrit

As I won't be using the oil pump the water/oil pump drive gear was cut down in width to 7 mm. The standard gear weighs 246 g, the modified gear 152 g.

Ligjtweight Swingarm pivot sleeve

Posted: Tue Jul 27, 2021 12:32 am

by KR-1R

Swingarm pivot sleeve bearing race

In silver medal position, and running 3 years behind Gerrit...

The Gerrit Sleeve type 2

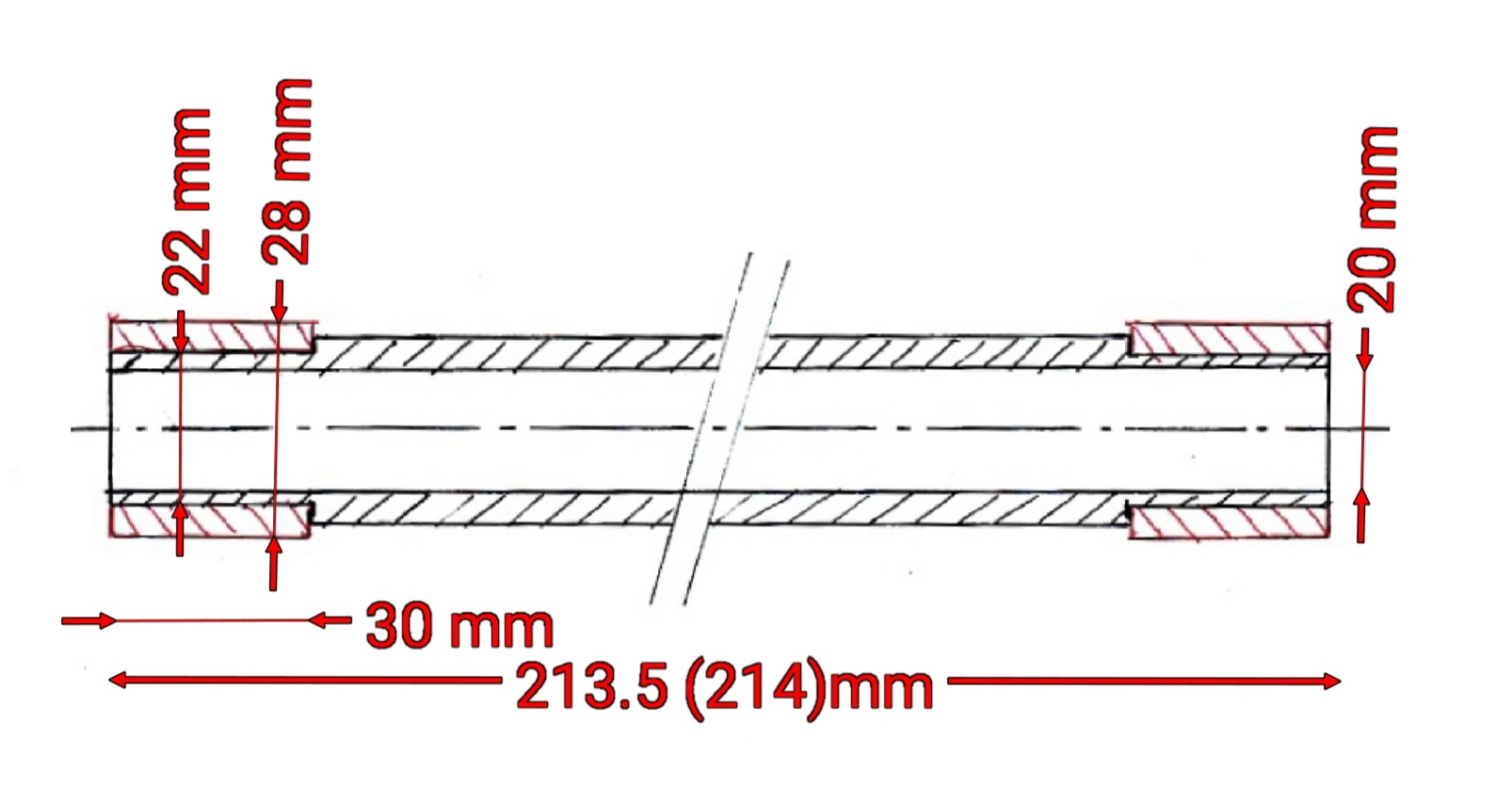

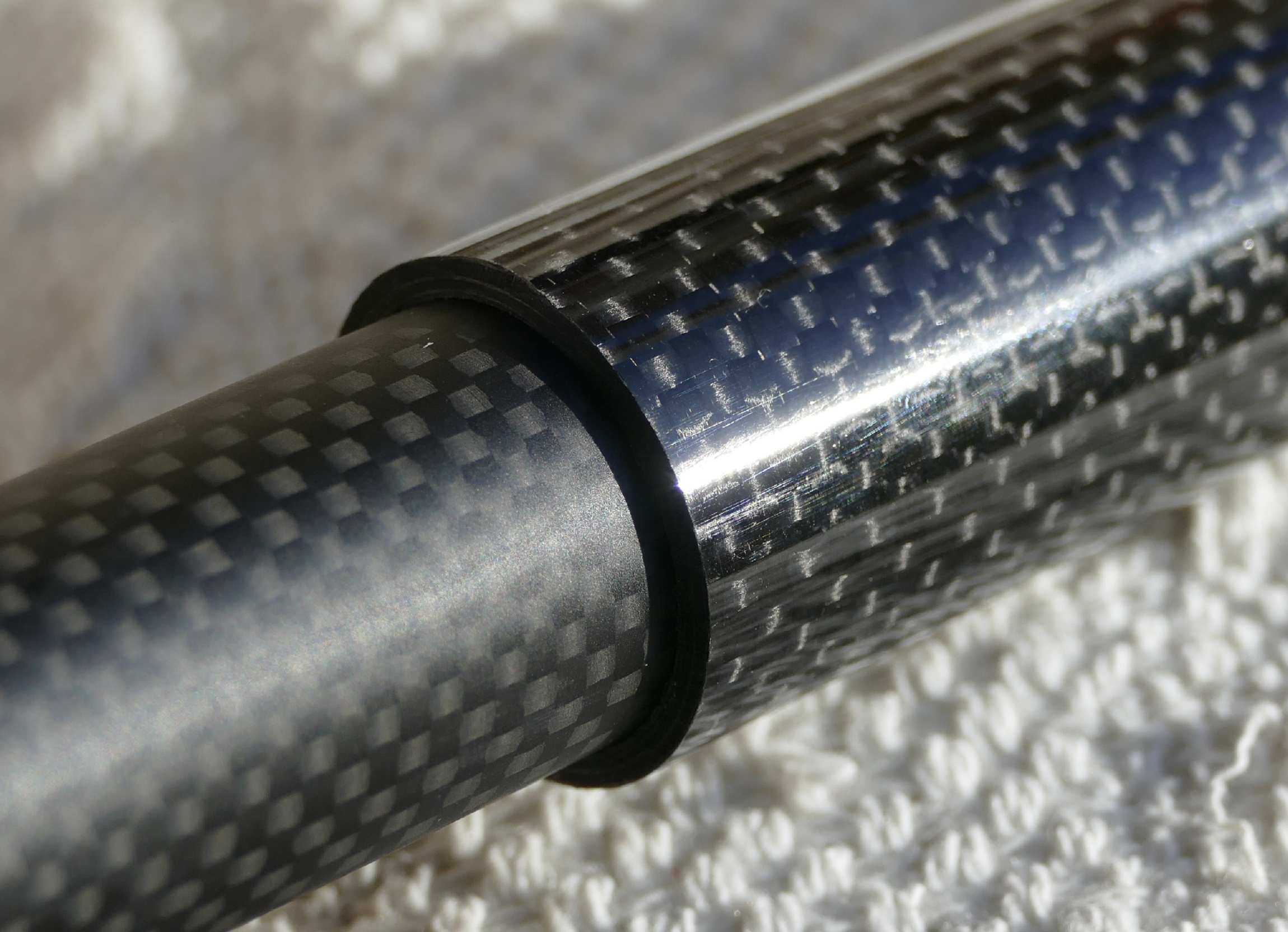

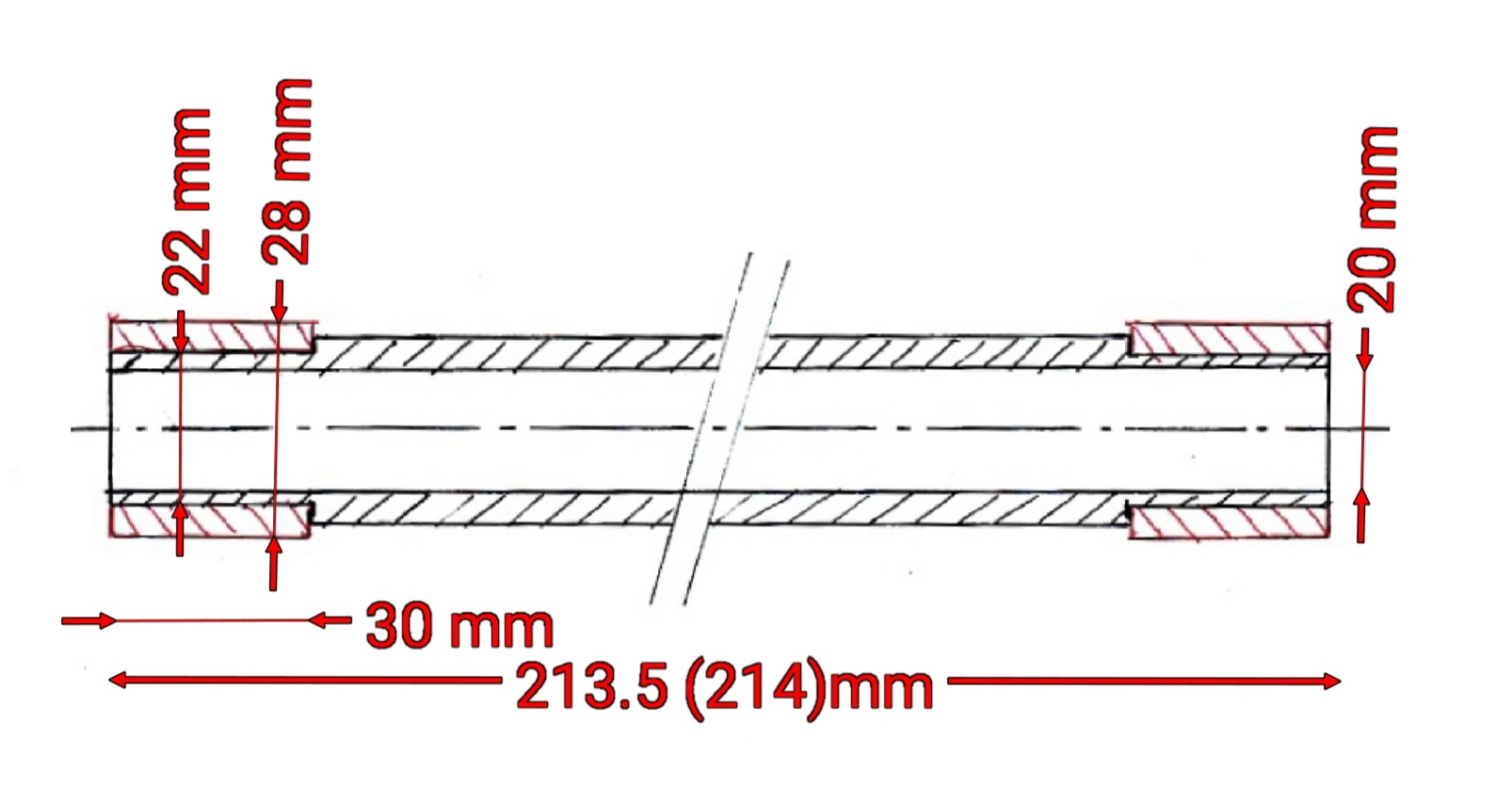

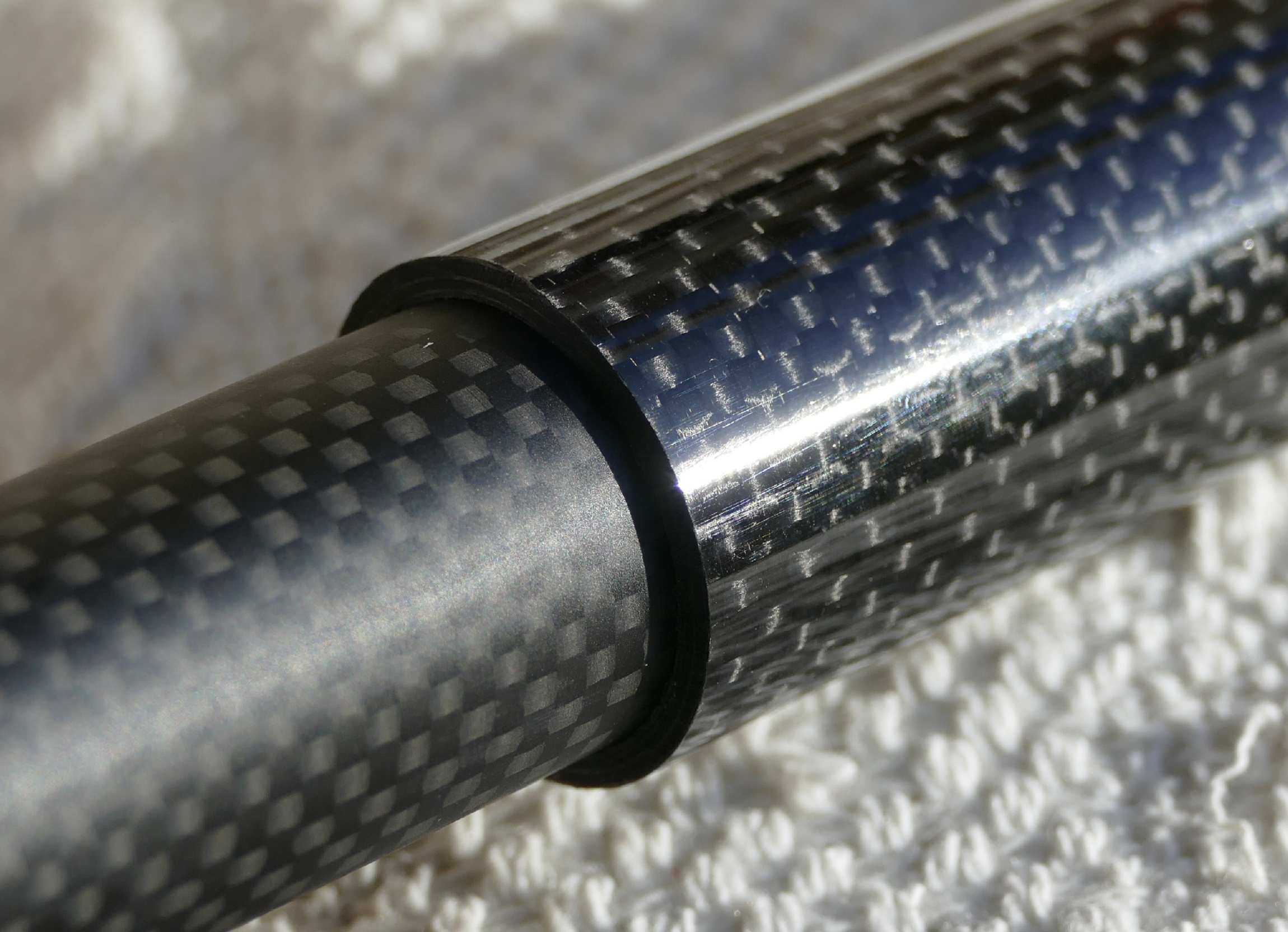

A 22x20mm matte plain carbon tube full length within a 26x22mm glossy bearing ring spacer (compound tube construction)

The assembly is held in compression, I dont see shear will happen at the step cthrough the 1mm wall tube.

Slender ratio (buckling) is limited by the close tolerance of the 20mm pivot bolt

NTN 1R22X28X30 inner race has square shoulders

Further alternatives with chamfers to INA brand is

IKO IRT2230-1, IKO LRT222830

TIP: normally the swingarm bolt should be thoroughly greased along the shank so it can not rust and bind inside the OEM steel swingarm sleeve requiring MJ43 'doorway' removal method

Re: Hybrid project

Posted: Tue Jul 27, 2021 9:29 am

by Gerrit

I did briefly consider carbon fibre rather than titanium, but I couldn't find any info on carbon fibre's behaviour under compression. Tightening the swingarm nut might cause the carbon tube to compress too much, which is why I decided for titanium as its properties are well known. The carbon fibre tube would of course save even more weight than the titanium part would.

You would of course have to bond the bearing sleeves to the tube with some sort of adhesive.

Re: Hybrid project

Posted: Tue Jul 27, 2021 12:03 pm

by KR-1R

Your idea is a clever one

I dont have a lathe and was trying to do things cheaply as possible with minimal tools

Tubes £20, bearing rings came to £10 (which i thought were very cheap)

Each tube came 500mm long so should be able to make two out of

I have to overcome the tight fit of the concentric tubes and the ring on the dia22, both may be solved with heating the outer and freezing the inner before assembly. Failing that some sanding

Mine still has to be finished and tested

The left over lengths of tube i have will go toward wheel hub spacers

Type 3 would be alloy tube with rings bored out to ID 24mm

Re: Hybrid project

Posted: Tue Jul 27, 2021 10:15 pm

by JanBros

only 1mm thickness where the bearrings come ?

Re: Hybrid project

Posted: Wed Jul 28, 2021 1:35 am

by Gerrit

If you succeed in making the tube assembly you could test its behaviour with a length of 20 mm threaded rod and two nuts plus washers. Clamp one of the nuts in a vice, assemble and tighten the second nut to the recommended torque value. Admittedly a crude test but you can then measure the compressed length and see whether there is any significant compression. Do wear eye protection in case the carbon fibre shatters. You could use a pivot bolt instead of the threaded rod but then you'd have to make two spacers to compensate for the frame thickness.

Re: Hybrid project

Posted: Wed Jul 28, 2021 5:14 pm

by KR-1R

.

.

If there is significant compression the bolt wont tighten (like a marshmellow)

Just as when you tighten a tension bolt - if it starts to yield it stretches the more its tightened,

As it stretches it 'necks down' losses diameter until force put into overwhelms the reduced diameter , it gives up and snaps with a characteristic angled shear failure

Jan theres no shear force directly on the 1mm

The pinch of the left and right sides of frame puts the sleeve into compression

The force travels thru Inner Rings that butt up against 22x26 tube eg 2mm thick

At the same time both the 1mm and 2mm tubes are both carrying the load equally

Thin wall buckling shouldnt occur because of the weave and restraint of bolt

IF I put it inside the swingarm/frame and tighten and it goes Ping - no goggles were required - unforeseen consequences

IF i put in, tighten, no Ping, go for a ride, Ping, whats the worst to happen? the rings become like a bush and the swingarm might move 3° ?

Its not Neil Armstrong in a plane at extreme altitude loosing loss of control surfaces due to no air density

Re: Hybrid project

Posted: Thu Jul 29, 2021 11:06 am

by Gerrit

I've found a paper in pdf form titled "On longitudinal compressive failure of carbon-fibre-reinforced polymer: from unidirectional to woven, and from virgin to recycled" (what a mouthful!). Hopefully it will shed some light on behaviour of carbon fibre under compression e.g length reducion.