This might take a while!!!

-

mavesyn

- Newbie

- Posts: 22

- Joined: Wed Jun 24, 2009 10:40 am

- Location: Staffordshire

Re: This might take a while!!!

Enjoying the post, cracking engine pics, nice to see it all laid out on the work bench.

- 500bernie

- Avgas Sniffer

- Posts: 3396

- Joined: Mon Aug 02, 2010 10:22 am

- Location: Teesside

-

Luders

- Avgas Sniffer

- Posts: 3926

- Joined: Fri Jun 18, 2010 11:29 am

- Location: Oxfordshire

Re: This might take a while!!!

Is it these bits you're referring to?

-

DougB

- Oil Injector

- Posts: 590

- Joined: Thu Dec 12, 2013 9:58 pm

- Location: York

Re: This might take a while!!!

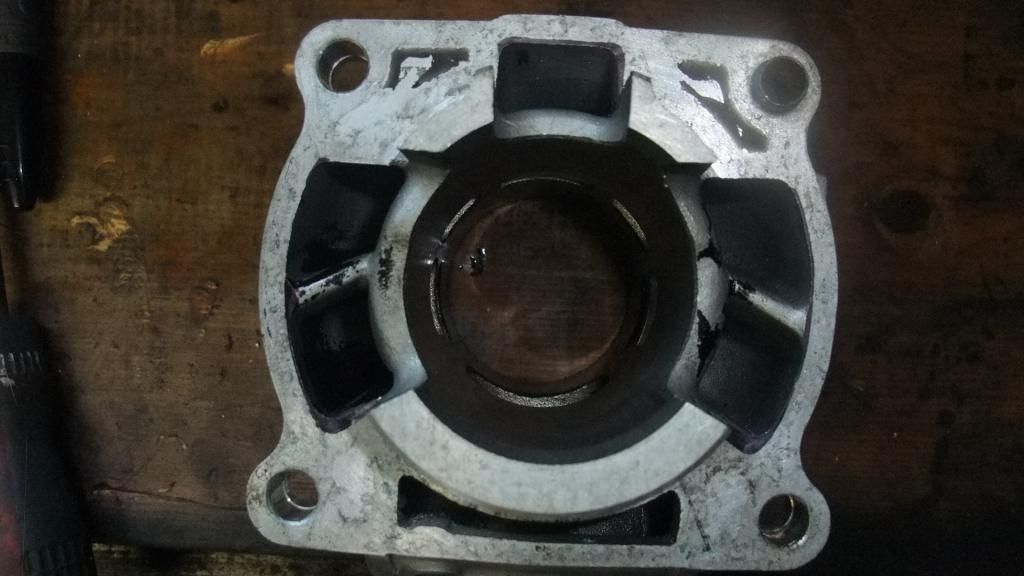

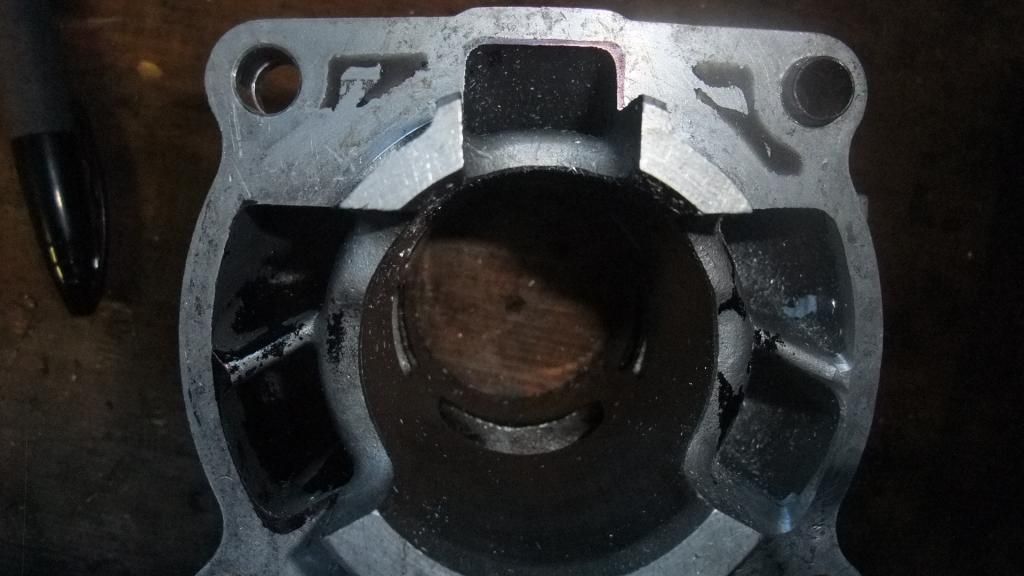

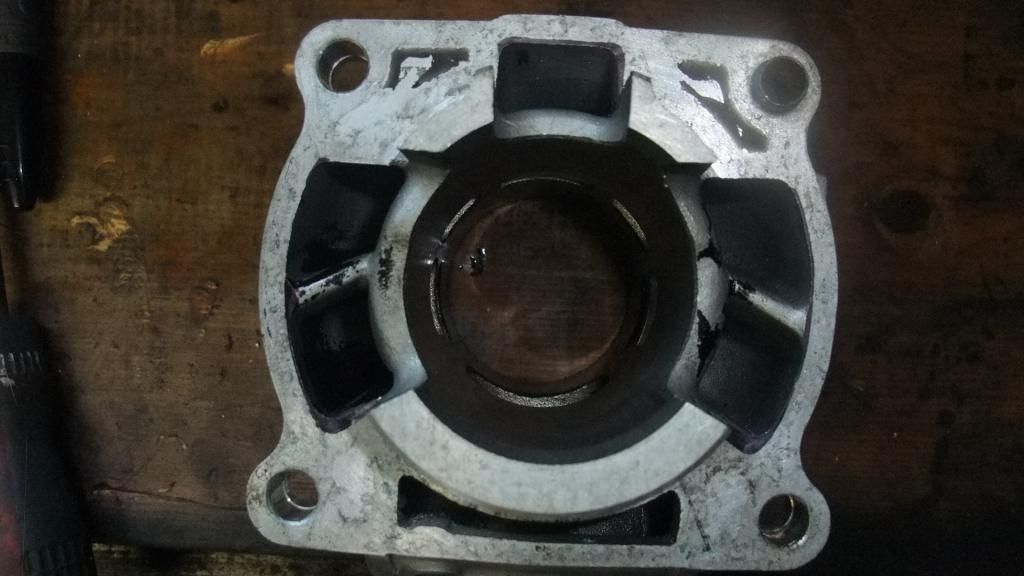

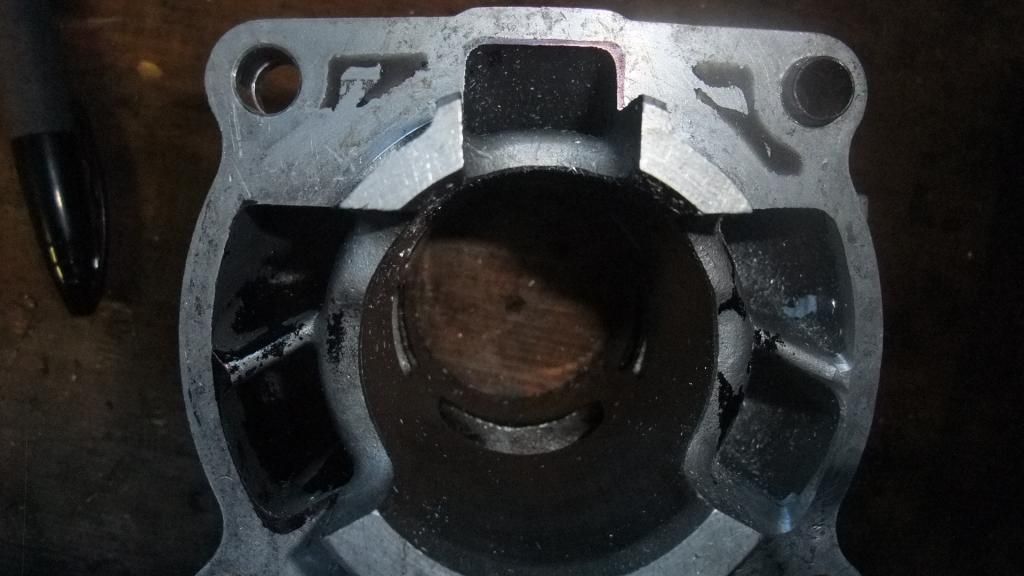

That's it, I've tried to show it in these pics. Barrel loose assembled onto the crank case, the barrel casting seems to come a long way into the casing and with no real shaping/flow and is right in the transfer port area. The crank is at SEP now so I can't connect up the piston and see how much of that area the skirt runs down onto. I know that area of the barrel is supporting the piston skirt around BDC but have you ever tried any re-profiling of that bit and do you think it would have any impact?

PS see that step in pic 1 into the centre transfer port

PS see that step in pic 1 into the centre transfer port

-

DougB

- Oil Injector

- Posts: 590

- Joined: Thu Dec 12, 2013 9:58 pm

- Location: York

Re: This might take a while!!!

Will do Bernie, I'm enjoying this500bernie wrote:Keep the photos coming Doug

- tescr500

- Oil Injector

- Posts: 742

- Joined: Sat Aug 29, 2009 12:05 pm

- Location: hampshire

Re: This might take a while!!!

Hi Ben I only use the cheep cheep ones, they last well, went through 1 dremel and 1 jcb one, JCB still going though,, but have got a Parkside cordless from lydl for back upLuders wrote:I've been through 3 dremels this year, they're shit, but cheap and do a decent job while they're working

Have you looked up the info on what to take out and fill on these cases?

No Matter How Messy Things Get You Can Always Clean Them Up.

MY MAMMA TOLD ME, IF YOU AIN'T GOT ANY PROBLEMS DON'T MAKE ONE.

TIME IS PRECIOUS WASTE IT WISELY

MY MAMMA TOLD ME, IF YOU AIN'T GOT ANY PROBLEMS DON'T MAKE ONE.

TIME IS PRECIOUS WASTE IT WISELY

-

Luders

- Avgas Sniffer

- Posts: 3926

- Joined: Fri Jun 18, 2010 11:29 am

- Location: Oxfordshire

Re: This might take a while!!!

Some people trim that section down like this

I use shorter pistons with less skirt, so don't mess about with it on my engines and I'm not convinced you gain much by grinding it away.

I use shorter pistons with less skirt, so don't mess about with it on my engines and I'm not convinced you gain much by grinding it away.

-

DougB

- Oil Injector

- Posts: 590

- Joined: Thu Dec 12, 2013 9:58 pm

- Location: York

Re: This might take a while!!!

Thanks for that pic, my other worry would be how altering the shape might change the piston clearance when it's hot? Anyway, think I'll leave it. I've got another set of barrels that I might play with a bit more over next year and can always try going a bit further with them and trying them in the future. Got enough grinding and filling to be on with in the meantime.

-

Luders

- Avgas Sniffer

- Posts: 3926

- Joined: Fri Jun 18, 2010 11:29 am

- Location: Oxfordshire

Re: This might take a while!!!

I don’t mess with them and get plenty of power from my race engines. I'm about to start my latest soon, so dyno figures will be available in a couple of months.

-

DougB

- Oil Injector

- Posts: 590

- Joined: Thu Dec 12, 2013 9:58 pm

- Location: York

-

DougB

- Oil Injector

- Posts: 590

- Joined: Thu Dec 12, 2013 9:58 pm

- Location: York

Re: This might take a while!!!

Work on the first barrel, the Dremel works pretty well.. Still debating with myself whether to do the crankcase flowing work but so far so good. Hope all this effort and ringing ears makes a difference [-o<

Hard to see but black marker showing how much needs to come off around the edges of the side and rear transfers

A bit clearer (ignore old gasket glue and odd black paint inside the ports, not sure what that's doing there?)

First transfer done

Quicker work on the rear

Last one sorted

Bit of work just to straighten some of the edges, then onto the next one..

Hard to see but black marker showing how much needs to come off around the edges of the side and rear transfers

A bit clearer (ignore old gasket glue and odd black paint inside the ports, not sure what that's doing there?)

First transfer done

Quicker work on the rear

Last one sorted

Bit of work just to straighten some of the edges, then onto the next one..

-

Luders

- Avgas Sniffer

- Posts: 3926

- Joined: Fri Jun 18, 2010 11:29 am

- Location: Oxfordshire

Re: This might take a while!!!

The crankcases are worth doing

-

DougB

- Oil Injector

- Posts: 590

- Joined: Thu Dec 12, 2013 9:58 pm

- Location: York

Re: This might take a while!!!

I can see definitely see why. The only bit putting me off is the filling, trusting in chemical metal (out of interest what brand do you use?). Years ago a rep from JB weld came to us and showed us a picture of a valve seat repaired back into an alloy head using filler to repair the surround, it was pretty impressive. My worry is that with combustion, expansion etc eventually it comes out, that's a fair lump to come adrift into the crankcases on the KR.

I'd love to do it to see the effect, but as it's a reliable road engine I'm wanting I'm balancing the risk really. For a race engine I appreciate every few horses is worth more risk up to a point.

Once I've got both barrels done and the cases matched up I'll see.

I'd love to do it to see the effect, but as it's a reliable road engine I'm wanting I'm balancing the risk really. For a race engine I appreciate every few horses is worth more risk up to a point.

Once I've got both barrels done and the cases matched up I'll see.

-

Luders

- Avgas Sniffer

- Posts: 3926

- Joined: Fri Jun 18, 2010 11:29 am

- Location: Oxfordshire

Re: This might take a while!!!

You don't have to fill if you have any reservations, just do the flow work.

I use the JB Stick to do all my filling and so long as you prep the area, it sticks like a limpit to a rock. Never had a failure.

I use the JB Stick to do all my filling and so long as you prep the area, it sticks like a limpit to a rock. Never had a failure.

-

DougB

- Oil Injector

- Posts: 590

- Joined: Thu Dec 12, 2013 9:58 pm

- Location: York

Re: This might take a while!!!

Both barrels done so they can go off for plating now.

Think I will flow the cases but leave out the filling. I've got my spare motor to go at next year so think I'll have a go at those cases and try the JB weld as well.

A list as longer than an arm to be getting through now so I'll be busy enough..

Think I will flow the cases but leave out the filling. I've got my spare motor to go at next year so think I'll have a go at those cases and try the JB weld as well.

A list as longer than an arm to be getting through now so I'll be busy enough..